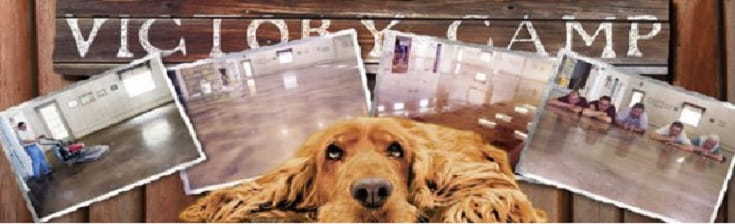

The camp sun was unseasonably warm. Gentle waves lapped soothingly against the sandy lakeshore. While an uncharacteristically inactive yellow lab retriever dozed peacefully nearby, a determined work crew was busy inside the mess hall getting a ten-year-old concrete floor ready for a new crop of summer campers.

The Tulsa-based crew from Concrete Visions, Inc. was using a high tech diamond grinder and turning the well-worn Victory Camp mess hall concrete floor at Mannford, Oklahoma, into a beautiful glossy surface. The plan called for a series of progressively finer grinding steps. The crew used a new, patented, dust-free dry grinding and polishing process similar to terrazzo grinding but without the mess of a water-borne slurry. The powerful diamond-grit grinder and vacuum system professionally removed over sixty mils of aging epoxy coating. The epoxy and concrete dust was completely contained as it passed through a powerful vacuum into attached, thick-walled plastic bags. There was no airborne mess to contend with or control.

As the dense concrete floor became exposed, to everyone's surprise it was discovered that the almost 80-foot-by-60-foot floor had no precut joints. For all its use, the floor had suffered only three hairline cracks, and those were tightly closed and difficult to see. The dense concrete floor was then progressively dry polished to its final gloss level, finishing with very fine, 1500-grit diamonds.

After grinding the floor to the final gloss, the scope of the work called for the floor to be stained and then sealed to provide an attractive and long-lasting finish. The uniquely formulated acid-based stain would not etch away the floor's hard-won gloss. The sealer, similarly, was unique in that it would insure a long lasting, low maintenance floor finish for the camp staff.

The next step in completing the scope of work was to seal and harden the floor. The Concrete Visions crew is a certified installer of FGS PermaShine, a patented dry grinding and polishing system available exclusively through LATICRETE® International, Inc. A key component of the FGS PermaShine system is its chemical hardener and densifier, FGS HARDENER PLUS™. This product is specially designed to harden and densify worn and ground concrete floors, restoring them to their original durability, without leaving a surface film.

FGS HARDENER PLUS™ also minimizes the long-term maintenance costs of this system. It locks in the stain and reduces the need for costly periodic reapplications of topcoat sealers, so common with acid-stained concrete. As required by this process, the crew professionally installed a double application of FGS HARDENER PLUS™ liquid.

Further gloss testing was performed on the stained and sealed floor, along with static coefficient of friction (SCOF) testing. Independent testing by the National Floor Safety Institute (www.nfsi.org) has shown that FGS PermaShine floors are safe, classifying them as "High Traction," with SCOF readings of above .60, under worst-case, wet conditions.

The final result was a beautifully stained, sealed, and glossy mess hall floor ready for use by legions of excited summer campers for years to come. Those campers will likely be unaware of the value added this spring to their dining experience. Camp operators, on the other hand, are well aware of the long-term benefit of a well-planned and executed floor rejuvenation system. They now have an attractive, safe, long-lasting and low maintenance concrete floor that will provide its benefits for many more summers of "Camp Fun-in-the-Sun."

Your next beautiful concrete floor is probably right under your feet, within the floor you already possess. It's just waiting for you to release its potential. Get acquainted with FGS PermaShine floor system, and you'll be on your way to your own beautiful floor!